In the ever-changing world of production, efficiency and accuracy optimization are critical. The use of linear motion systems, also known as uniform motion, has become a ground-breaking remedy that is transforming the manufacturing and assembly processes. You will explore the many advantages of using uniform motion in manufacturing in this in-depth tutorial, which will highlight the ways in which this technical innovation improves output, precision, and overall operational effectiveness.

1. Enhanced Precision and Accuracy:

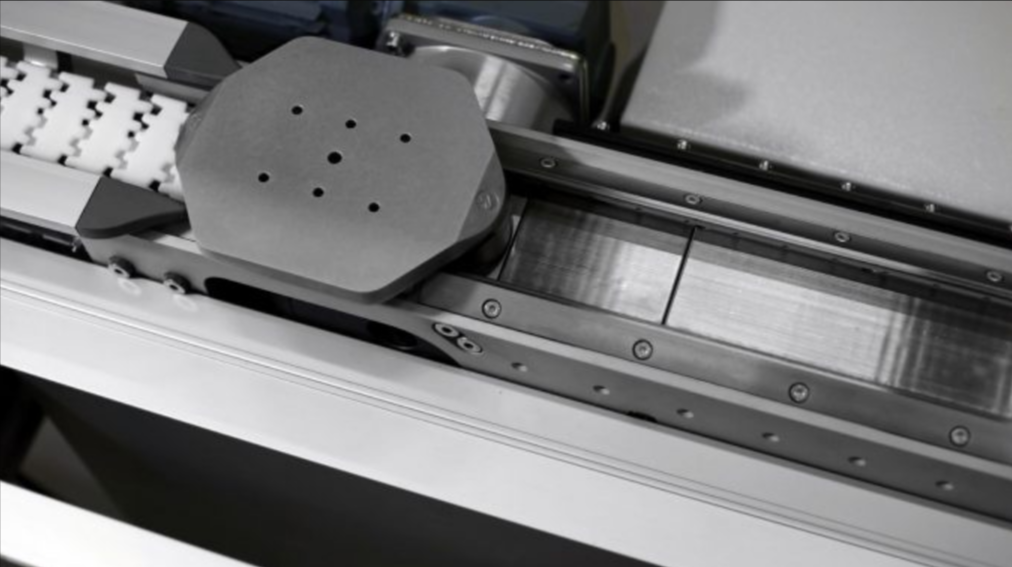

The unmatched accuracy and precision that uniform motion provides to the manufacturing process is one of the main benefits of incorporating them. Conventional manufacturing techniques are prone to human error and often depend on manual labor. On the other hand, Rollon linear motion systems function with robotic accuracy, guaranteeing that every part is positioned and assembled exactly in accordance with predetermined requirements. These systems provide precise control over component movement by using cutting-edge technology like encoders and stepper motors. This degree of precision is especially important in sectors where even minute variations might result in faults or flaws in the products.

2. Increased Production Speed and Throughput:

Manufacturing processes may run faster and with higher throughput thanks to linear motion systems, which also increase efficiency to unprecedented levels. In contrast to physical constraints that restrict human work, uniform motion may function at high and constant rates without sacrificing precision. This faster rate of production is particularly helpful for businesses where deadlines and demand are critical. The productivity savings are further enhanced by the seamless integration of uniform motion with other automated processes, resulting in a production line that is synchronized and optimized.

3. Flexibility and Adaptability:

Given the changing nature of customer tastes and market developments, contemporary production must be flexible and adaptable. When it comes to offering a versatile and flexible industrial environment, uniform motion shines. These systems are perfect for businesses where frequent product variants or customization are the norm since they can be quickly programmed and reprogrammed to match changes in production needs. Uniform motion provides the flexibility needed to execute changes smoothly, such as introducing a new product line, modifying the assembly process, or adjusting component specifications. This flexibility reduces the need for significant retooling or reconfiguration of production lines, which makes it both a cost-effective option and a strategic advantage in meeting market needs.

4. Improved Worker Safety and Ergonomics:

The integration of linear motion systems greatly enhances the production environment’s worker safety and ergonomics. Conventional manufacturing methods sometimes include risky circumstances, repetitious labor, and the physical manipulation of large, heavy materials. By automating a large number of these operations, uniform motion lessens the physical strain on employees and lowers the possibility of workplace accidents. As essential parts of uniform motion, robotic arms and conveyor systems may move large objects and carry out repetitive operations continuously, relieving people of potentially hazardous and taxing responsibilities. In addition to making the workplace safer, this frees up human workers to concentrate on harder, more intellectual jobs that call for creativity and problem-solving abilities.

5. Cost Savings and Improved Efficiency:

When uniform motion is used in production, operational efficiency is increased and real cost savings are realized. These systems may appear like a big initial expenditure, but in the long run, the advantages are significantly greater. Uniform motion minimizes related expenses and maximizes the production of high-quality goods by reducing the possibility of faults and rework via their accuracy and speed. Furthermore, you may make more units in a given amount of time because of these systems’ enhanced throughput and adaptability, which improves total production efficiency. Labor costs are also reduced by automation since fewer human workers are required to do repetitive and routine activities. Furthermore, a lot of uniform motion’ predictive maintenance features help to cut down on downtime and avoid expensive equipment problems.

Conclusion:

Using uniform motion in manufacturing is a calculated move that completely changes the way that production is carried out while providing unmatched accuracy, speed, and flexibility. The advantages include greater worker safety, flexibility, faster production, more accuracy, and significant cost savings. Adopting these technical innovations gives your production facility a competitive advantage in the dynamic and constantly changing industrial scene by putting it at the forefront of efficiency and innovation.