One of the most critical aspects of an expanding business is its warehouse management system. With the right warehouse Inventory Management system, growing businesses can identify improvement areas while boosting production, performance, and overall productivity.

An up-to-date warehouse management system also helps to track workflow, raise efficiencies across the different phases, maximize asset utilization, improve space usage, and boost operational effectiveness. As a business owner looking to optimize your workflow and warehouse management system, you can check warehousing and logistics out and how they are helping more business owners to enjoy the advantages of a warehouse management system.

Some of the advantages of a warehouse management system include;

Reduced Operating Expenses and Improves Space Optimization

Many businesses face space management problems. However, an effective warehouse management system can address this problem by streamlining the warehouse flow and charting the most effective storage design. Leveraging such management solutions can help businesses store more products and items while eliminating the common errors that could lead to damage.

With an effective warehouse management system, business owners enjoy an in-depth analysis of their current floor plans and space usage. They also get insights on how they can improve their storage, utilize space better, and identify areas where they can reduce waste.

This solution can also effectively reduce material transportation, the time taken to stock and retrieve products, and operating expenses.

Improves Inventory Visibility

Inventory visibility is a major problem with the manual warehouse management process. Chances are high that older inventories may be pushed to the back, increasing the chances of damages and losses. However, with a warehouse management software solution, businesses can now keep track of their products and inventories while perfecting the First In, First Out (FIFO) order process.

By leveraging a warehouse management system, businesses enjoy;

- Accurate and real-time information about their inventory levels

- Anticipated rise or fall in demand and supplies

- Reduction in backorders

- Happier and more satisfied customers

Businesses can enjoy the best outcome when they combine their warehouse management system with scanning, RFID, and other location-tracking systems. This helps them get better inventory visibility, push out older products while stocking newer ones from the back, and more.

Improved Labor Effectiveness

Labor ineffectiveness is one major way manufacturers and businesses lose money. Employees should do the right thing at the right time to cut latency, improve effectiveness, and boost productivity.

With a warehouse management system, businesses can allocate the right tasks to the right person with the requisite skillset. This means more employees will get tasks tailored towards their skills instead of handling tasks outside their job description

By allocating the right tasks to the right people, the time taken to figure out each task before attempting them is significantly reduced. This means employees will get more work done in a shorter time than when they had to handle tasks outside their skillset.

Material Traceability

Time is lost when employees search for materials or products. The time that could have been put into valuable tasks could be lost as they shuffle through the warehouse. This time wastage is addressed when an effective warehouse management system is deployed.

With an effective warehouse management system in place, each product/material is tagged appropriately with a lot, batch, and serial number. This improves identification and directs employees to the right spot when locating orders, products, or materials.

Material traceability also reduces theft as there is an updated inventory of where each material or product is stored and how they are processed out of the warehouse.

Optimized Supply Chain

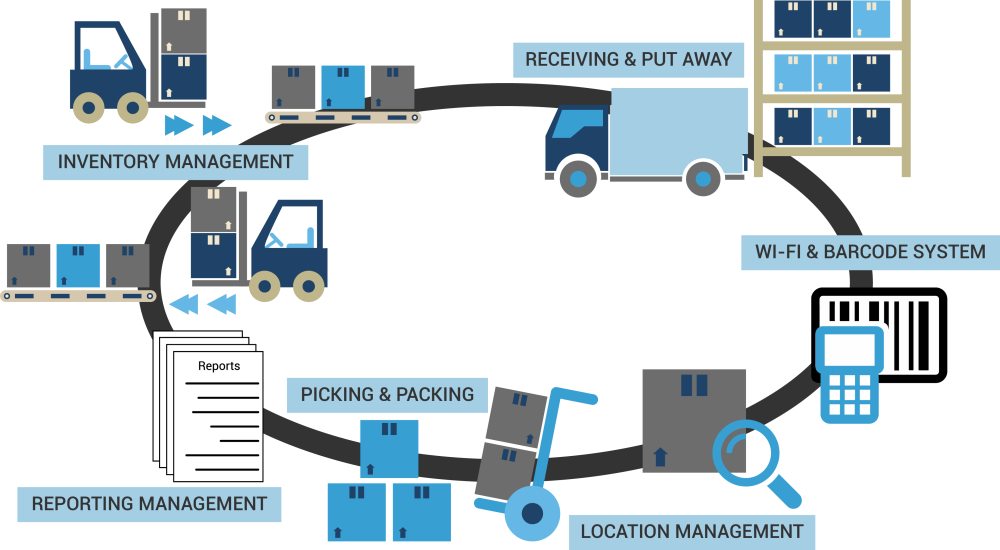

Operational efficiency is one of the biggest advantages of a warehouse management system. Business owners get a chance to reduce their overhead costs by streamlining the entire warehouse process from the receipt stage to the delivery phase. With the appropriate solution, business owners can reduce the non-productive activities that take time and guarantee faster shipments to customers.

Internal Automation Advantage

Internal automation improves the work and product flow. With appropriate internal automation, employees can now handle certain tasks digitally without standing or wasting time. This can significantly cut down on wasted time, improve processing times, and boost delivery times to customers.

Internal automation also improves data accuracy and scalability and helps businesses identify areas where they can improve their practices. This automation can also form the baseline for other processes, including capturing and recording inventory and communication across the business.

Businesses can leverage warehouse management systems to improve their performance, operation, and bottom lines. If your business isn’t already leveraging this solution, you may be losing a lot more and cutting into your potential bottom line.